Digimatic Caliper Calibration Procedure

**INSTRUCTION**** ** ** ** **1\. Range of application** This technical document specifies the calibration of digimatic calipers with up to 600 mm in me

Contents

INSTRUCTION

1. Range of application

This technical document specifies the calibration of digimatic calipers with up to 600 mm in measuring range and 0.01 mm resolution.

3. Calibrating instruments

3.1 Standard measuring instrument (s)

Caliper checker:

- Range of Measurement: (20 ÷ 300) mm

(20 ÷ 600) mm

3.2 Other measuring instrument (s)

Inside and Outside Micrometer:

- Range of Measurement: (0 ÷ 25) mm

(5 ÷ 30) mm

- Resolution: 0.001 mm

- Accuracy: ± 1 μm

± 5 μm

3.3 Supporting instrument (s)

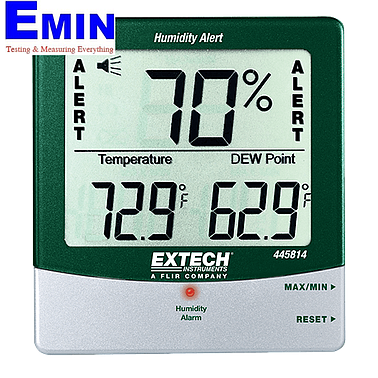

Hygro-Thermometer:

- Range of Measurement: (0 ÷ 50) °C

- Accuracy: ± 0,5 °C

- Range of Measurement: (10 ÷ 95) %RH

- Accuracy: ± 3 %RH

4. Auxiliary Instrument(s)

- Specialized cleaning solution and towel

5. Conditions for Calibration

- Temperature: (23 ± 5) °C

- Humidity: no higher than (50 ± 15) %RH

8. Reliability Evaluation

9. General handling

a. The calibrated caliper is stamped, certified in paper along with calibration results, and measurement uncertainty.

b. The recommended calibration cycle of digimatic caliper is 12 months.

10. About EMIN's Calibration - Verification - Repair center

EMIN Vietnam’s Calibration and Verification center has been established since 2020 to provide after-sales services. The Calibration and Verification center is thoroughly equipped with technical equipment, followed by the assistance from various equipment manufacturers around the globe. At the center, calibration of specialized equipment is successfully carried out by experienced engineers in EMIN Vietnam, ensuring fast, accurate, reliable procedure to meet the most demanding customers’ requirements). Such technical capacity can only be performed by very few technology businesses in Vietnam. Meanwhile, after tireless effort, the Calibration and Verification center of EMIN Vietnam is officially certified to be accredited by the ISO 17025 standard (Jan, 2021)

If you want your instruments calibrated, please contact:

Equipment Verification - Calibration - Repair Service Center - EMIN Vietnam JSC

Address: No 203 Nguyen Ngoc Vu Street, Trung Hoa Ward, Cau Giay District, Ha Noi City

Email: services@emin.vn - Hotline: 0968.060.220

Further information about digimatic calibration service can be found here.